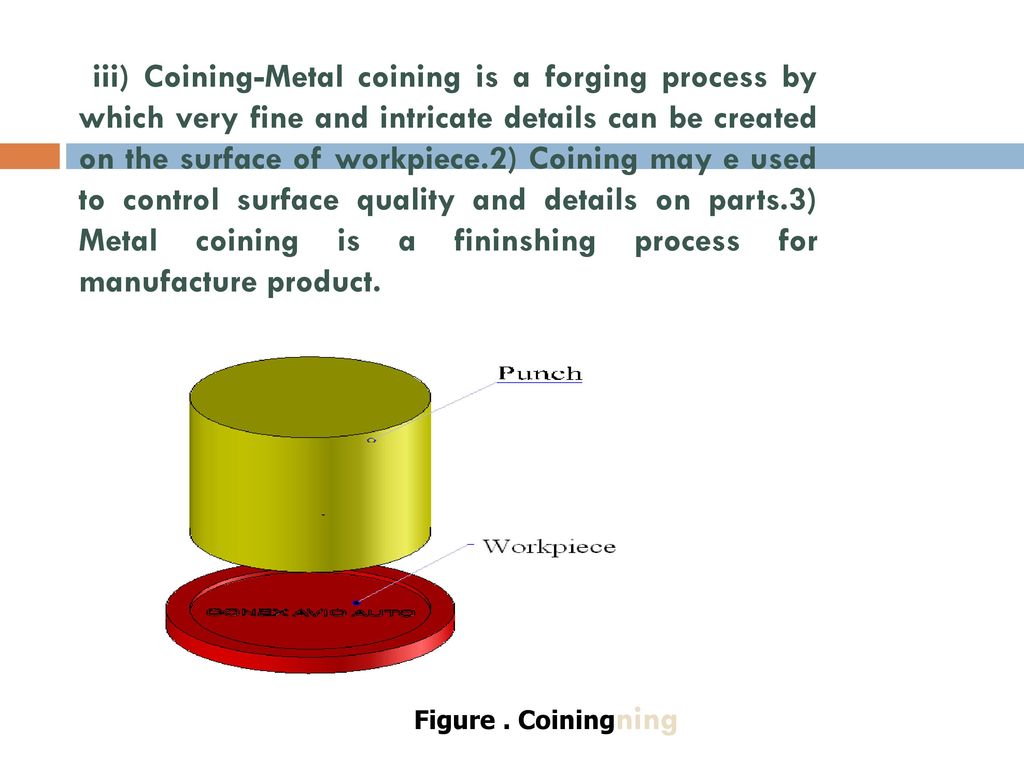

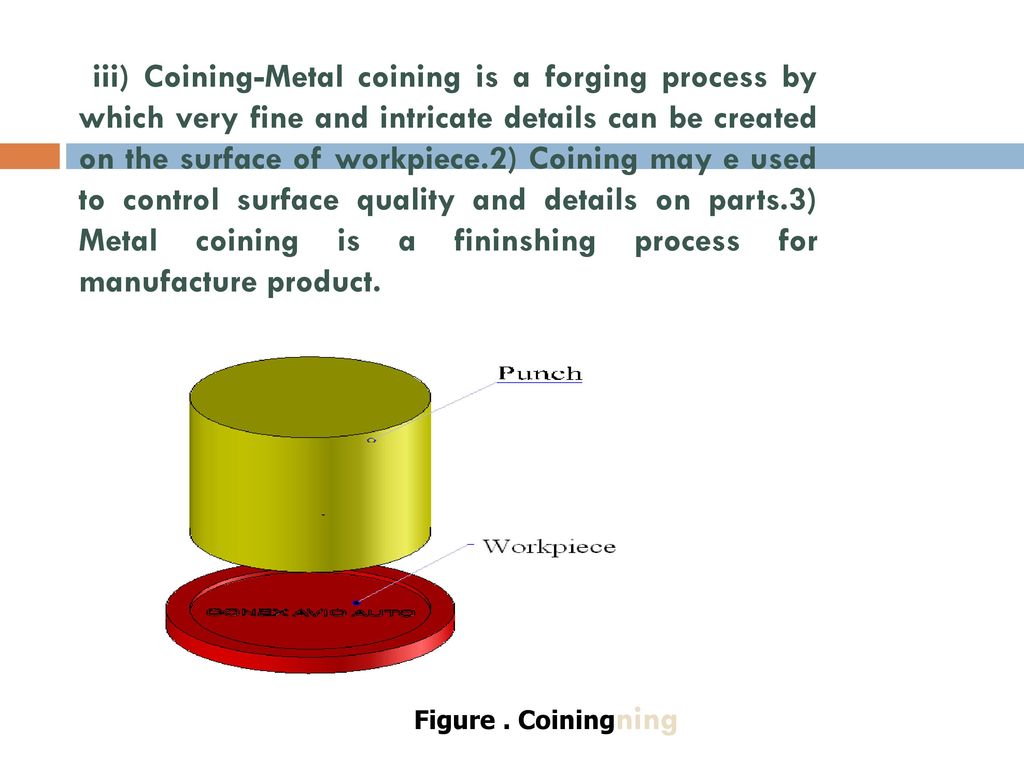

Coining dies create the part s shape by squeezing the metal under extreme pressure.

Coining operation in sheet metal.

Coining is relatively severe.

It is a cut in a straight line across a strip sheet or bar.

This is used for making works on metal like coins medals etc due to the fact that it produces finer and detailed.

Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure.

It leaves a lean edge on the piece of metal is sheared or cut.

Embossing is an operation in which sheet metal is drawn to shallow depths with male and female matching dies.

What you need to know about coining coining is a metalworking operation used to create raised surfaces and imprints in metal.

The operation is carried out mostly for the purpose of stiffening flat panels the operation is also sometimes used for making decoration items like number plates or name plates jewelry etc.

Coining also can reduce the metal thickness.

Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material.

A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it see figure 3.

Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die.

And the punch is hit at the other end of the sheet producing a shearing effect.

A beneficial feature is that in some metals the plastic flow reduces surface grain size and work hardens the surface while the material deeper in the part retains its toughness and ductility.

In this operation a sheet metal workpiece is placed or kept between two dies from one end.

Embossing operation with two dies.