The concrete and the reinforcing steel need to be cut through from top to bottom and slabs as thick as 1m have been cut by giant group using the cold cutting method.

Cold cutting steel plate methods.

We used a 2 saws that have carbide c.

A cold saw is a circular saw designed to cut metal which uses a toothed blade to transfer the heat generated by cutting to the chips created by the saw blade allowing both the blade and material being cut to remain cool.

For free hand and plate type cutting steel definitely a plasma cutter if you can afford one.

That is where plasma is tricky.

Doing a head to head comparison on the fastest way to cut thick steel.

Unfortunately most of the methods require expensive tools and years of training to perform the cut safely.

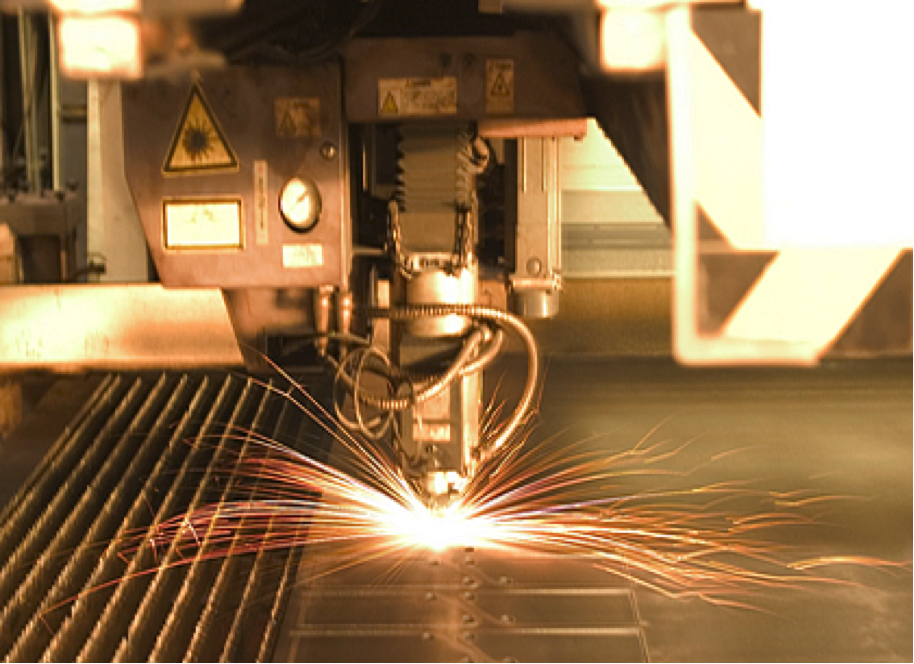

The high energy infrared focused beam of laser cutting provides a cut width of less than one millimeter or kerf minimising material loss.

Benefits of cold cutting cold cutting has a number of significant benefits in relation to traditional cutting techniques which generate friction heat and sparking and in some application.

Cut through multiple materials and layers in a single pass.

There are numerous methods of cutting a steel plate at home.

The cut finished edges leave something to be desired compared to some of the other steel cutting methods above but it s much better than a cutting torch and this tool will do lots of things other methods just can t.

One cutting method uses an.

Dismantle above ground storage tanks.

This is in contrast to an abrasive saw which abrades the metal and generates a great deal of heat absorbed by the material being cut and saw blade.

Precision cutting of steel concrete asphalt fiberglass tank linings pipe etc.

Laser cutting high precision and productivity.

Quality of cut tolerance and production speed are critical performance issues.

Single pass mobile cold cutting using ultra high pressure water jet technology for cutting storage tank floors roofs and side shells.

This enables a controlled demolition of concrete.

Plasma arc cutting is a great process for cutting mild steel plate offering much higher speeds than oxy fuel cutting but sacrificing some edge quality.

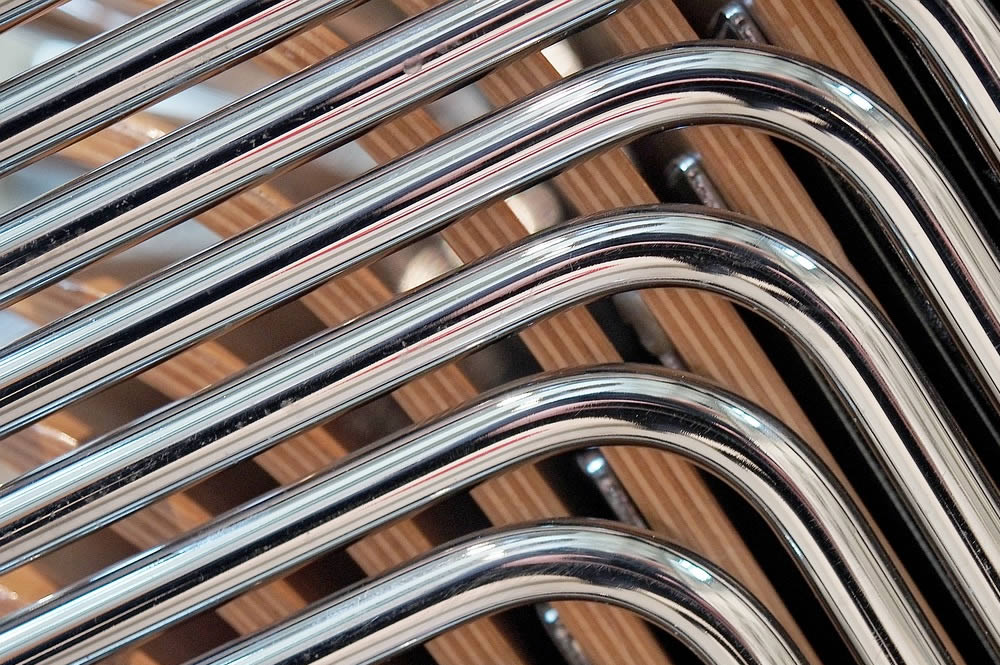

There are different methodsto cut stainless steel sheets and technical aspects have to be valuated to choose one.

Edge quality has a sweet spot that depending on cutting current generally ranges from about 1 4 inch up to 1 5 inches.

Uhp offers cold cutting to a wide range of applications in the chemical petrochemical oil gas offshore construction power steel and heavy industries.