This specialty line of food grade compressed air filters was designed with the high demands of the food industry in mind.

Compressed air filtration for food contact.

Compressed air must be contaminant free to ensure the protection of the food products processed in each facility.

That means that the air coming in contact with food or food contact surfaces should present no risk to food safety.

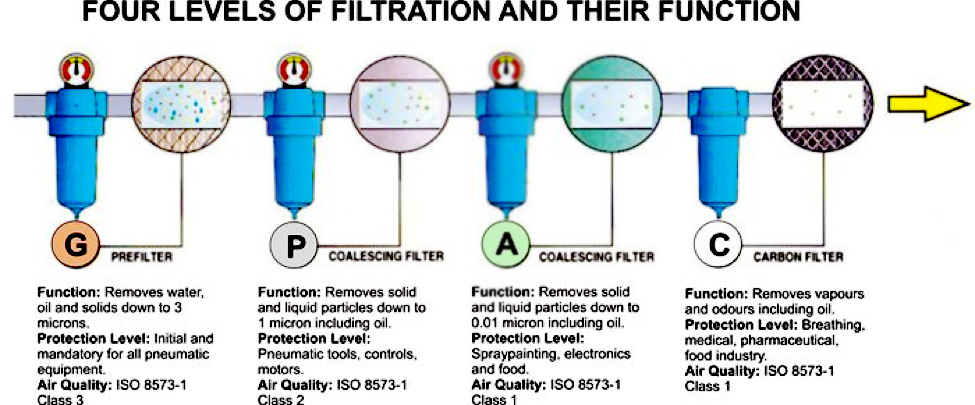

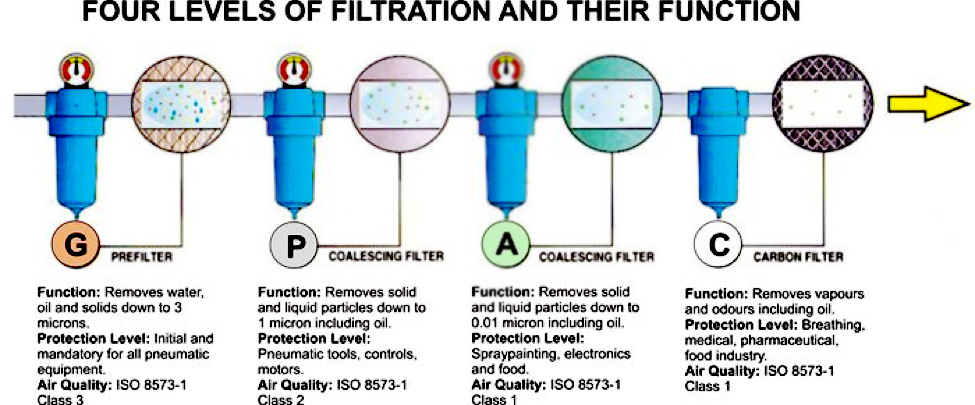

Code of practice for food grade air helps define three types of compressed air systems and air purification specifications required for each.

Various standards need to be met based on different applications.

The sqf auditor looks to make sure manufacturers have the proper point of use filtration in place to ensure clean safe air.

Bottled water donaldson s full suite of process filtration technologies ensures that the final product meets global food safety standards.

What is an acceptable micron size for compressed air filters.

A single test at one point in time is not enough.

This air is in contact with a soy protein isolate powder.

Compressed air coming in contact with food is a best practice.

Therefore by installing sterile air filtration at the point of use where it comes into contact with food or food contact surfaces you will meet or exceed gfsi 21 cfr and all published food safety codes relative to compressed air quality in a food processing plant.

They are made with certified non toxic powder coating and are excellent for washdown environments which are common in food processing.

Sqf has no specific standard.

The compressed air comes into direct contact with the product or is used to automate a process provide motive power package products or even to generate other gases on site a clean dry.

British compressed air society bcas 3 and the british retail consortium brc 4 seems to be widely accecpted.

Parker balston 3 stage point of use filtration modules in standard and 304 stainless steel housings will remove contaminants at a very high efficiency up to 99 99 for 0 01 micron.

Compressed air systems are dynamic and the compressor intake is subject to microbial particulate and moisture variations throughout the year as well as buildup of contamination in the system.

We currently use 0 01 micron primary filter.

Using sterile grade air is one of the most effective ways of reducing food safety risk.

For instance there is a higher standard when air comes into direct contact with the product so to meet the required standards and save costs nex flow has provided a list of some regulatory body quality factors and impacts of contaminants.

Food grade compressed air filters.

We re the industry experts in quality compressed air gas steam and liquid filtration.

Filtration fluid gas handling hydraulics pneumatics process control.

Compressed air filtration posted in sqf food.