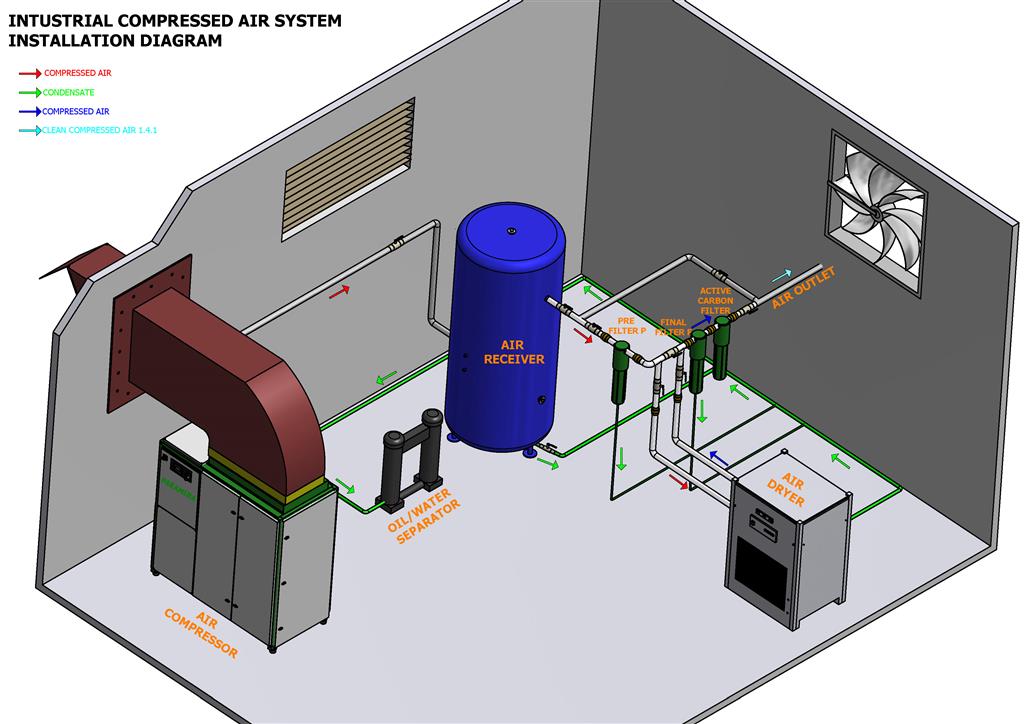

However designing a compressed air system is more difficult than you might imagine the compressed air has to be delivered with sufficient volume good enough quality and enough pressure to power the components that require compressed air.

Compressed air system design software.

A great deal on a larger compressor may look appealing initially but seldom does anyone point out the additional electrical costs incurred to run it over the ten or so years it will be in operation.

To deliver compressed air to where it is needed.

Too often we see the wrong compressors installed for the application.

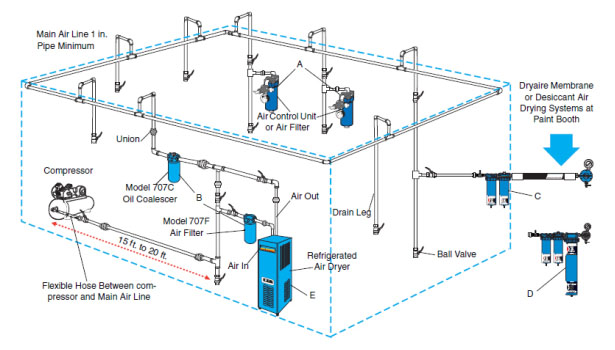

Along the way there is a risk of contamination and pressure drops.

Example 10 size pipes for compressed air system.

I work at a coal mine that uses compressed air.

Compressed air system design.

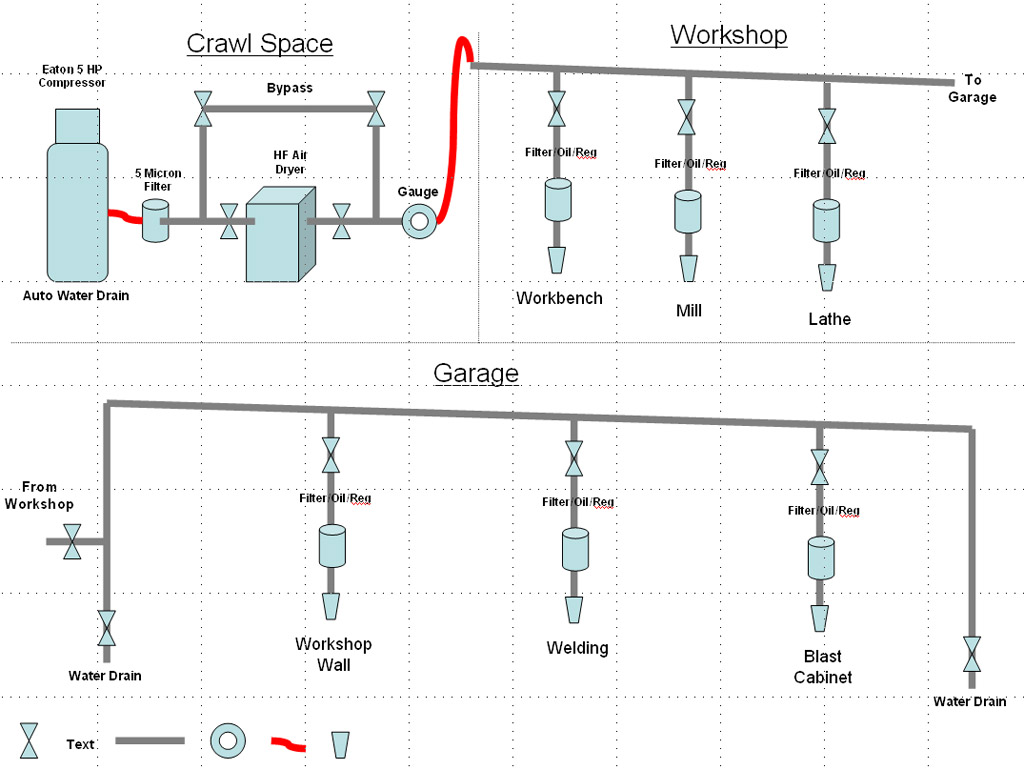

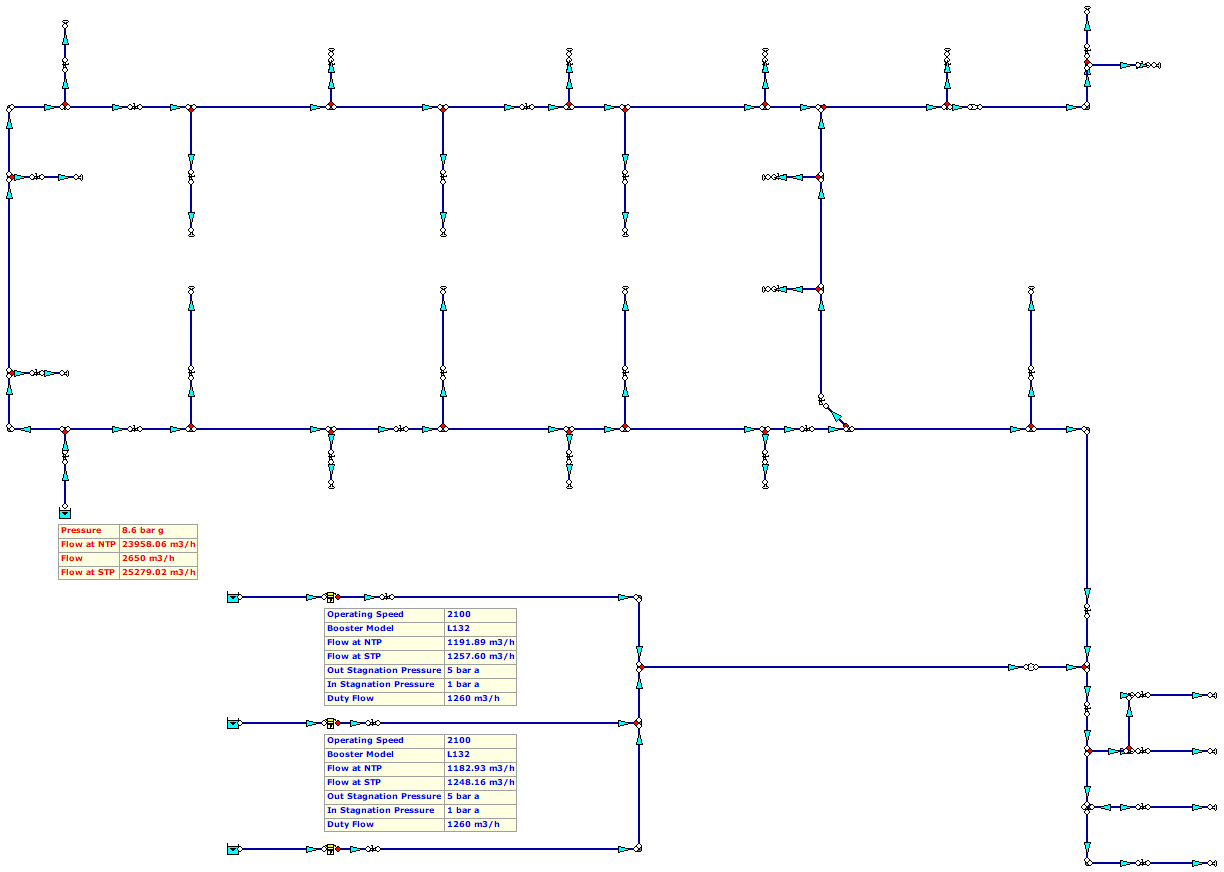

Compressed air system piping design this example shows a compressed air system where the air is distributed around a ring main loop system to maximize distribution efficiency when some demands are not in use.

Once air is compressed dried and filtered it is sent to an end use.

We have two large compressors on the surface and pipe the compressed air underground.

Compressed air system design.

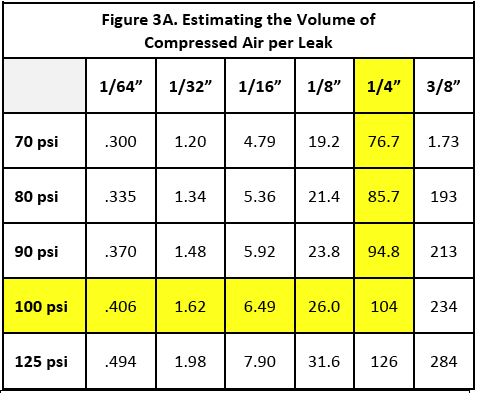

Occasionally a large pressure drop in the piping system is compensated by adjusting or increasing the working pressure of the compressor from for example 7 bar to 8 bar.

Parker transair offers a design software program to help you produce system layout drawings and quotations for your compressed air vacuum or inert gas aluminum systems.

We are at the beginning of our mine life and.

Piping is a vital component in a compressed air system.

The system is getting rather complicated as the mine grows with multiple branch lines and over a hundred points of use.

Keep these five factors in mind when designing your compressed air piping system to help minimize risk of dirty or poorly pressurized air.

A compressed air system simulation provides energy and performance data.

The purpose of compressed air piping systems is simple.

The planning and design of an air piping system are crucial steps to ensure optimal performance of pneumatic equipment and tools.

This helps companies make informed decisions as to which set up would be the best fit for the system.

Using a 3d grid you can build the piping layout and the software will generate a bill of material with all the components and pipe sections necessary for the final product.

In order to improve your knowledge of compressed air and guide you in your projects we provide you with reference guides and instructional videos on compressed air systems.